Menu

- Home

- Products

- Car Window Film

- Car Windshield Protection Film

- Chameleon Window Film

- Nano Ceramic Film

- UV400 Nano Ceramic Film

- Magnetron Nano Ceramic Film

- Magnetron Reflective Film

- Nano Carbon Film

- 2ply High Clarity HD Window Film

- DD Professional Dyed Film

- TT Economic Tint Film

- Paint Protection Film

- Paint Protection Film TPU

- Paint Protection Film TPH

- Colored Paint Protection Film

- Building Window Film

- Frosted Decoration Film

- Reflective Solar Control Film

- Colorful Decorative Film

- Dichroic Glass Film

- High Heat Insulation Glass Film

- Safety Security Film

- Clear Transparent Security Film

- Tinted Security Film 4mil 8mil

- Nano Ceramic Security Film

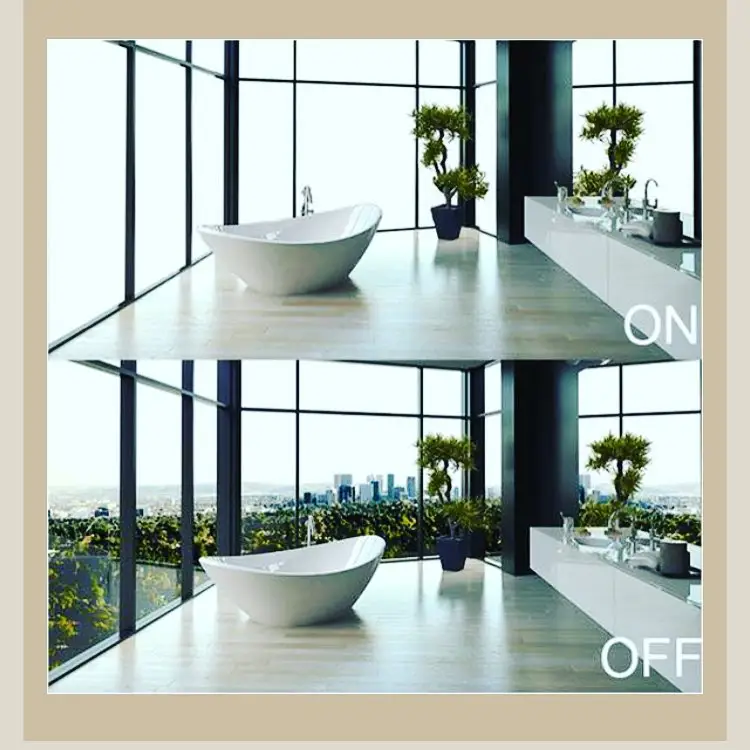

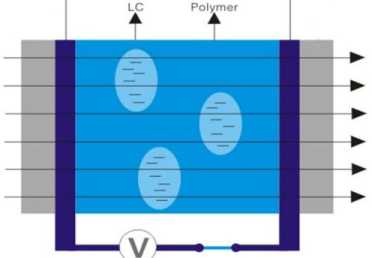

- Smart Glass Film

- Headlight Tint Film

- Car Wrap Vinyl

- Carbon Fiber Wrap

- Glossy Wrap Vinyl

- Matte Wrap Vinyl

- Chrome Metal Wrap Vinyl

- Pearl Glitter Car Wrap

- Chameleon Wrap Vinyl

- News

- Company News

- Industry News

- Product News

- Case

- Factory Show

- Dust free workshop

- Material area

- QC inspection

- The whole process of production

- large stock of ready finished goods ppf

- Contact Us

- About Us

- Company Style

- Certificate

- Exhibition

- FAQ

- Service

- Delivery

- Responsibility

Search